Use durostone to make PCB board, durable

April 19, 2023

Use durostone to make PCB board, durable

PCB board made of synthetic stone

PCB (Printed Circuit Board), the Chinese name is printed circuit board, also known as printed circuit board, printed circuit board, is the support of important electronic components and electronic components, and is the provider of electrical connections for electronic components. It is called a "printed" circuit board because it is produced electronically.

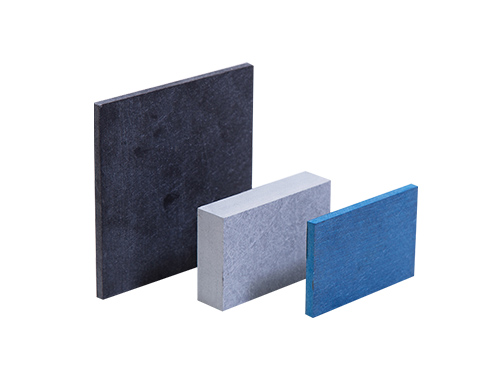

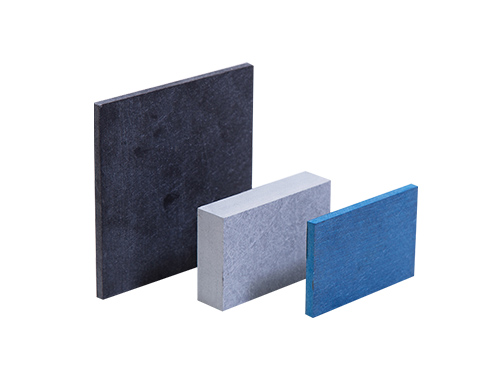

Synthetic stone: also known as high-temperature nanocomposite materials, generally used for reflow soldering fixtures; wave soldering fixtures; thermal insulation synthetic stone; flame-retardant synthetic stone; mechanical equipment synthetic stone parts and the like; Deformation; corrosion resistance; moisture resistance; wear resistance; pressure resistance and other characteristics.

Synthetic stone is produced from glass fiber compounds. The high heat-resistant composite material does not contain harmful ingredients to the human body. It has high mechanical properties and anti-static properties. Good high temperature resistance and moisture resistance make synthetic stone products not easy Deformation, synthetic stone has good workability. Used for synthetic stone plastic molds, synthetic stone injection molds, synthetic stone machinery manufacturing, synthetic stone forming machines, synthetic stone drilling machines, synthetic stone injection molding machines, synthetic stone motors, synthetic stone PCBs. synthetic stone ICT fixtures; synthetic stone loads Tools etc.

PCB boards made of synthetic stone also have the advantages of reducing costs, shortening production cycles, increasing productivity, reducing energy consumption, and improving finished products.

Features of synthetic stone

The main technical characteristics and applications of synthetic stone: good high temperature resistance, stable anti-static performance, long service life, synthetic stone has no deformation, good flatness, smooth surface, no pits, and thickness tolerance exceeds the standard. Suitable for the requirements of high-performance electronic products